How it Works

How FuelRx Works

How FuelRx Works

Increased Engine Life

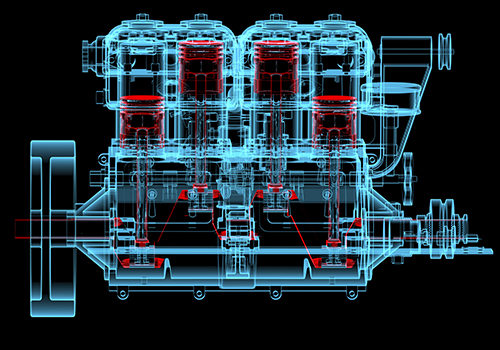

In contrast to typical solvent-based fuel additives, FuelRx does not get converted into a gas as it passes through the injectors. FuelRx also does not burn off prematurely. As a result of these positive properties, FuelRx not only does not cause pre-ignition, the chemical composition of FuelRx actually holds the burn of the fuel a fraction of a second longer. More of the fuel is burned more effectively. This results in more power on the downward stroke of the engine and more fuel efficiency.

As part of the combustion process, FuelRx comes into contact with the piston. FuelRx has the ability to deposit onto metal surfaces when in environments above 50 degrees Celsius. Interestingly and importantly, the product does not deposit onto itself. Thus, there is a surface layer of lubrication placed on to the piston, but that surface layer does not build up and flake off. The benefit here is increased engine life.

FuelRx - The Combustion Process

FuelRx - The Combustion Process

Normal fuel additives clean and then burn up. Our product does not burn up on the front end of the combustion process, thus it is available to continue cleaning throughout the remainder of the combustion process. The cleaning product effectively exists one inside the other. The first cleaning portion of the fuel additive does burn up in the combustion process leaving the second encapsulated cleaning portion intact to continue the cleaning process as well as lubricating the parts.

Marine applications use a product that avoids the uptake of water. We want to avoid the uptake of water because the centrifugal filter in the marine engines which is designed to remove water from fuel then results in turning the fuel into mayonnaise by whipping it up.

Diesel Bug Organisms

Diesel Bug Organisms

Diesel bug organisms refer to bacterial and fungal organisms that live in the water/organic fuel mix. If allowed to grow and reproduce, diesel bug will contaminate the fuel thereby reducing fuel combustion efficiency and clogging up parts. FuelRx kills the diesel bug organisms on contact prior to the fuel being brought into the combustion process.

Diesel bug organisms refer to bacterial and fungal organisms that live in the water/organic fuel mix. If allowed to grow and reproduce, diesel bug will contaminate the fuel thereby reducing fuel combustion efficiency and clogging up parts. FuelRx kills the diesel bug organisms on contact prior to the fuel being brought into the combustion process.

Fuel Tanks, Pressure Pumps & Storage Tanks

Fuel Tanks, Pressure Pumps & Storage Tanks

For fuel tanks attached to vehicles, there is often a low-pressure pump contained inside the fuel tank. On generators, the low-pressure pump is often located on the engine itself. The low-pressure pump is responsible for moving fuel out of the fuel tank to begin its journey to the combustion chamber in the engine. The low-pressure pump often uses the fuel itself as a coolant fluid and FuelRx both lubricates and cleans the pump. Lubrication and cleaning of this pump extends the lifespan of the pump and reduces the maintenance and replacement costs.

For fuel tanks attached to vehicles, there is often a low-pressure pump contained inside the fuel tank. On generators, the low-pressure pump is often located on the engine itself. The low-pressure pump is responsible for moving fuel out of the fuel tank to begin its journey to the combustion chamber in the engine. The low-pressure pump often uses the fuel itself as a coolant fluid and FuelRx both lubricates and cleans the pump. Lubrication and cleaning of this pump extends the lifespan of the pump and reduces the maintenance and replacement costs.

After being moved from the storage tank via the low-pressure pump, the fuel and FuelRx combination then travel to the high-pressure pump. The high-pressure pump of modern engines drives the fuel through extremely small holes in the injectors. This combination of high pressure and small injector holes means that the tolerances for good operation have been decreased significantly. The high-pressure pumps need to therefore be kept very clean and well lubricated.

The fuel and FuelRx at those pressures effectively act as a scrubbing brush that cleans everything. This cleaning is important because the holes in the injectors need to be kept clean for proper atomization of the fuel. If the fuel is not properly atomized, then the fuel comes out of the injectors as droplets instead of a spray. The droplet fuel does not burn as effectively or completely. The effect of this incomplete combustion is more carbon deposits on the piston and significantly reduced fuel efficiency.

The Combustion Chamber

The Combustion Chamber

Now we are at the point of injecting fuel into the combustion chamber. At this point on the top of the engine, temperatures are typically in the area 175 -225 degrees Celsius. The overwhelming majority of fuel additives on the market are solvent based causing them to burn off at this point and are no longer available to positively impact the rest of the combustion process. Solvent-based fuel additives also cause other problems because they have a lower combustion temperature than the fuel.

Now we are at the point of injecting fuel into the combustion chamber. At this point on the top of the engine, temperatures are typically in the area 175 -225 degrees Celsius. The overwhelming majority of fuel additives on the market are solvent based causing them to burn off at this point and are no longer available to positively impact the rest of the combustion process. Solvent-based fuel additives also cause other problems because they have a lower combustion temperature than the fuel.

The lower combustion temperature of the solvent-based fuel additives combined with the fact that these solvents enter the combustion chamber as gasses means that they ignite prematurely as well as causing the early ignition of the fuel inside the combustion chamber. When this occurs, the piston is effectively being pushed back down when it should be travelling up to meet the combustion at the top of the cycle as it would with regular diesel fuel. Clearly, the mistiming of the fuel combustion significantly reduces the power generated by the engine and reduces overall fuel efficiency.

The Exhaust Process

The Exhaust Process

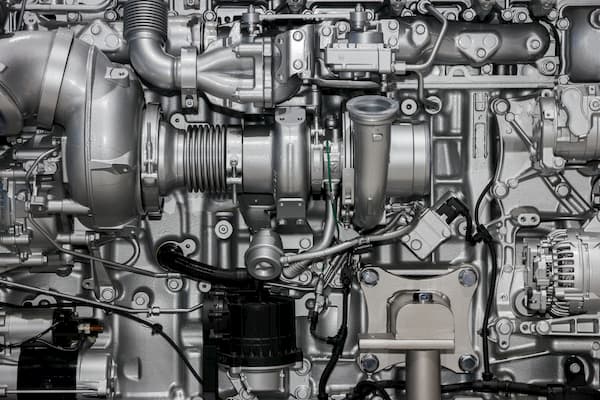

I n the next part of the process, we are at the exhaust and this starts with the turbo. The turbo gets lubricated and cleaned. This cleaning is being done by the encapsulated cleaner. Cleaning extends the life of the turbo and is important as this is the dirtiest part of the combustion process. This is essential because the turbos rate of rotation is very high speed. This cleaning process takes place over a longer period of time because much of the product is used up and you do not get the scrubbing effect as had been the case previously with the high-pressure pump.

n the next part of the process, we are at the exhaust and this starts with the turbo. The turbo gets lubricated and cleaned. This cleaning is being done by the encapsulated cleaner. Cleaning extends the life of the turbo and is important as this is the dirtiest part of the combustion process. This is essential because the turbos rate of rotation is very high speed. This cleaning process takes place over a longer period of time because much of the product is used up and you do not get the scrubbing effect as had been the case previously with the high-pressure pump.

We then proceed on to the EGR (exhaust gas recirculation valve). This EGR is lubricated and cleaned as well. The cleaner this part can be the better because it reduces the amount of dirt going back into the engine through the induction of air.

The DEF (diesel emissions filter) blocks up very quickly. This occurs because the amount of carbon coming through the system is significant due to the improper burning of the fuel. Our product does not really do anything special with the DEF itself. It is simply that due to all of the other good work that was done in each of the previous parts of the process, there is far less carbon particulate created as a result of more efficient burning of the fuel. Over a longer period of time, the DEF will be cleaned with the miniscule remaining portion of the additive. This is a longer term clean than any of the processes mentioned above.

Through the product development process, we learned that we were able to regenerate the lifespan of the rubber seals. This was not a specific goal of our design team, but it was a very nice surprise development.